The invasion has begun

Already, armies of automated machines are screwing bolts into cargo hulls, welding the seams of steel barrels, and palletizing foodstuffs. But are you ready to hire one for your business?

Employing a staff of robots might seem far off; as a business owner, considering its implications may strike you as unwarranted, even silly. Past predictions about future technology have been less than reliable. Flying cars still don’t exist, despite being enthusiastically foretold in the ‘50s.

But self-driving ones do…

Self-driving cars are about replace human drivers

Once the technology is sufficiently polished, robot-driven cars will eventually replace those operated by people. Some business experts estimates predict this will happen by 2020. Whenever it happens, the advantage is obvious: robots make fewer mistakes than we do.

Self-driving cars would prevent the millions of automotive deaths caused by human error (around the world, 1.25 million people are killed on roadways annually).

But the self-driving solution creates a new problem: ‘driver’ is among the most common occupations in the industrialised world.

In the United States alone, the transition to self-driving cars would eliminate at least 5 million jobs in a single gesture.

Many businesses are now grappling with these sorts of dilemmas; many more will soon.

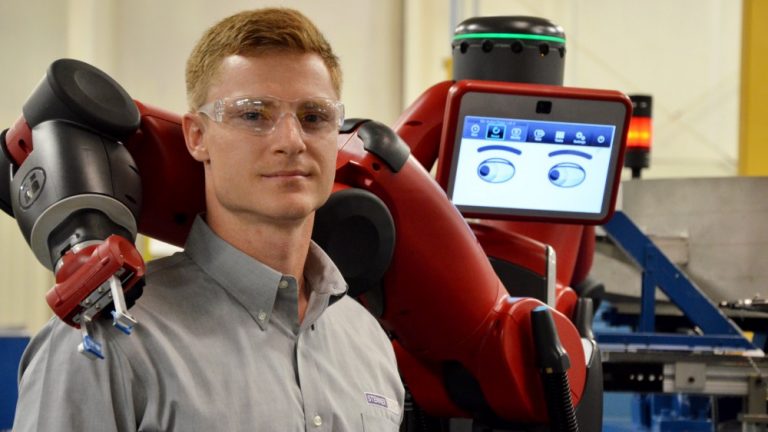

Small business factories are ready for robots

For small businesses, this question has never been more relevant, especially for small to medium-sized manufacturers.

New, collaborative robots, called ‘cobots,’ are being put to work on factory floors alongside people around the world.

Unlike earlier iterations of industrial robots, these are easily programmed with an inbuilt tablet (no expert required). Cobots’ sensors recognise when people are near, which switches them off — allowing them to work safely in close proximity with people.

Plus, they are now cheaper than ever, costing as little as $25,000.

Less than a decade ago, only large companies with deep pockets could afford to replace human labour with robotics, as the American automotive industry did with abandon during the beginning of the 21st century. But as prices for industrialised robots have plunged, their popularity has skyrocketed.

At present, cobots represent a small number of industrial robotics. Less than 4 percent of those sold last year fell into this category. But sales of cobots are on the rise, and have been growing by 75 percent year-over-year.

The ‘cobotics’ industry looks poised to explode

As the cost of a cobot is less than half the US median income, it’s not hard to imagine why. Robots, after all, can work 24-hours a day — and they’ll never ask you for a raise.

Actual robots don’t require smoke breaks. Or any breaks for that matter.

Some worry that robots will put enough people out of work to spark a global crisis. Others argue that this has already started, and that the much-lamented loss of factory jobs in the United States and elsewhere has less to do with globalisation and more to do with automation.

Manufacturers that employ robotics argue this new technology actually creates new jobs, and that by providing greater productivity, robots will increase everyone’s wealth.

Whether or not widespread robotic manufacturing will destroy jobs or create them is still an open question. But it’s one that will likely be decided among small businesses, as SMEs account for 70 percent of global manufacturing.

In Japan, where the population has been dwindling for decades, the labour force is scarce. But robots are ready to step in, and the Japanese seem ready to hire them:

According to a Bank of Japan survey, companies with share capital of 100 million yen to 1 billion yen plan to boost investment in the fiscal year that started in April by 17.5 percent, the highest level on record. (REUTERS)

Robots will one day soon change every industry

Robots are moving outside factories, too. Already, two hotels in Japan are staffed entirely by robots. In London, a media agency called BrainLabs introduced us its robotic receptionist earlier this year. Called ‘Pepper,’ this 4-foot machine can (supposedly) recognise human emotions, and adjust its responses accordingly.

So while robots have invaded factories first, they won’t stop there. As the technology improves and gets cheaper, it may soon make sense for you to have a robot stock your shelves, answer your phone, or greet customers.

We can be sure of at least one thing: as technology leaps forward, those businesses that are late to make the changes will be left behind.